07743989565

01482 420491

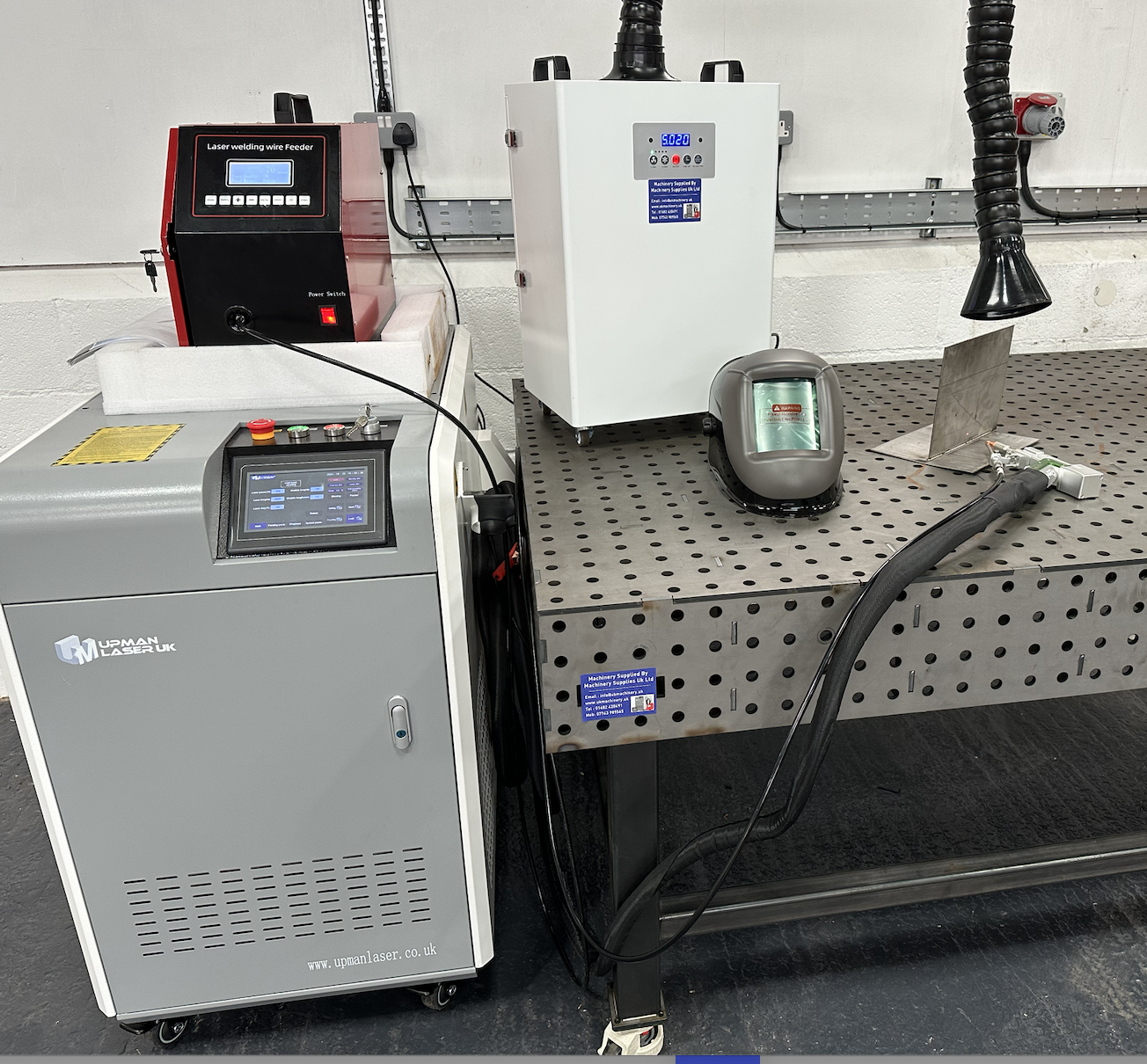

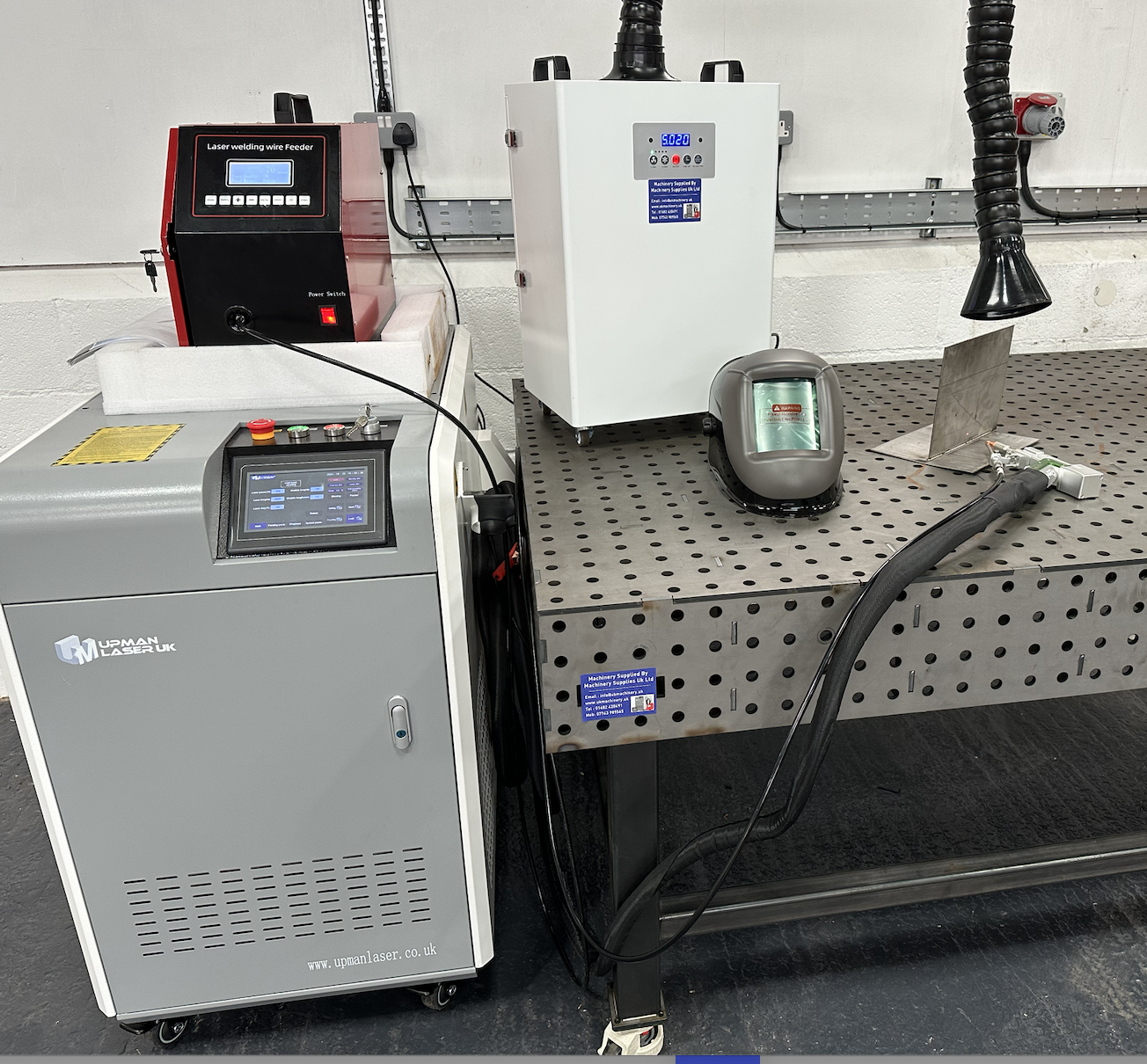

Fiber Laser Welding

We offer full UK Support and Training - Consumables

We have researched welding solutions and extensively tested the duty cycle and penetration levels to bring superior technology to your welding requirements.

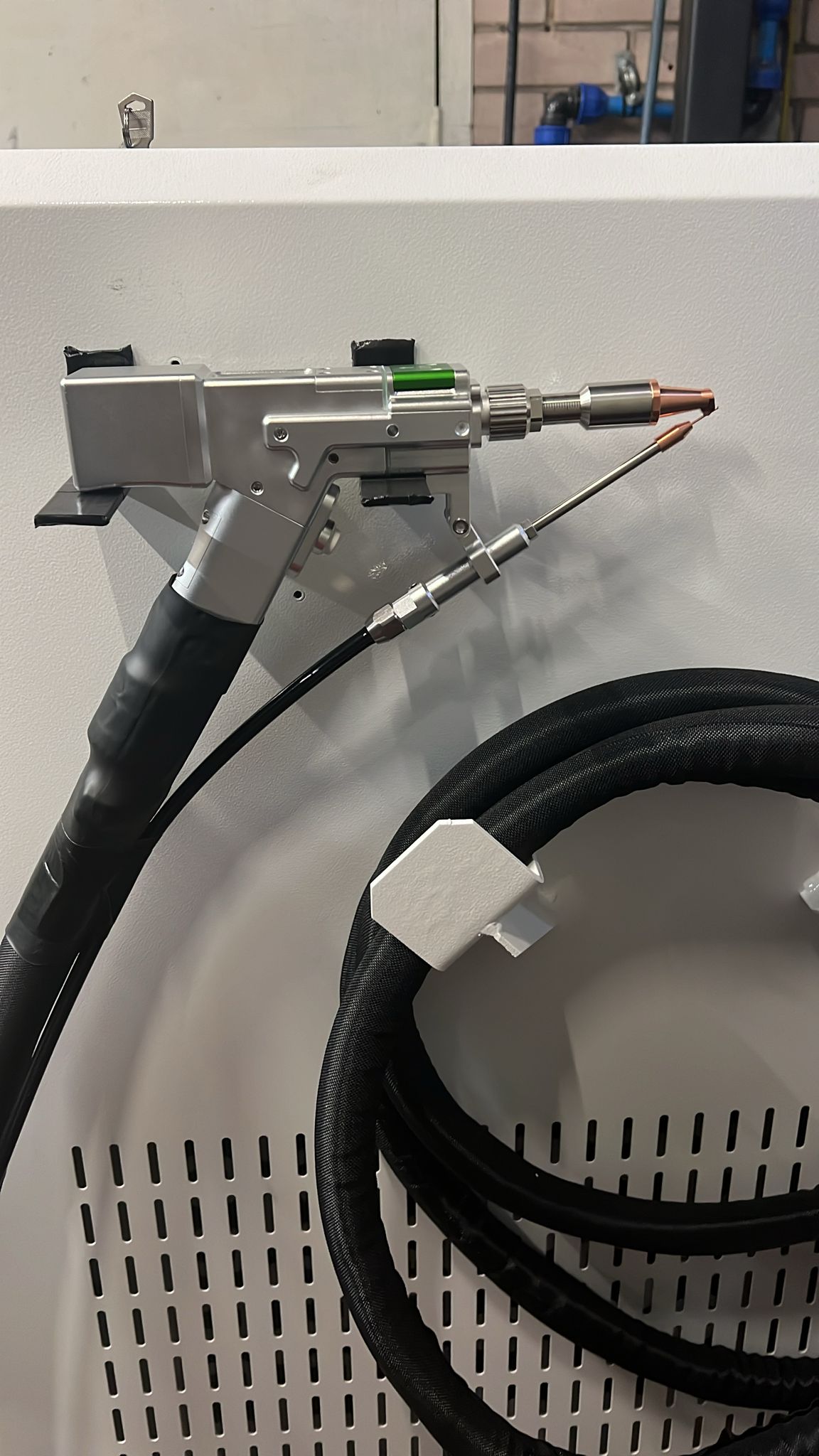

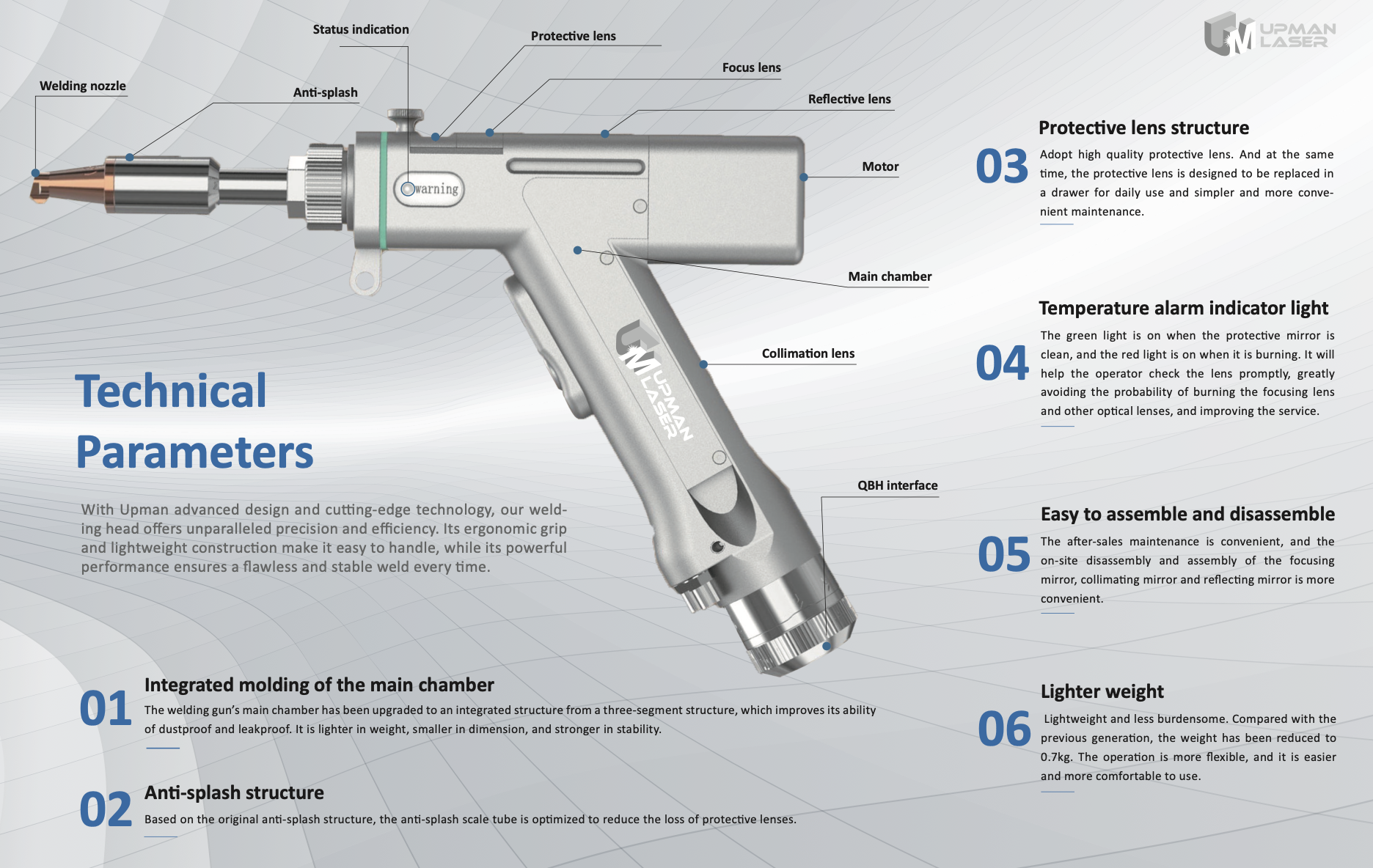

Coupled with Auto single or Double wire feed - Water Cooled with Refrigerant, Our Fiber welders are Simple - Efficient - Easy to operate

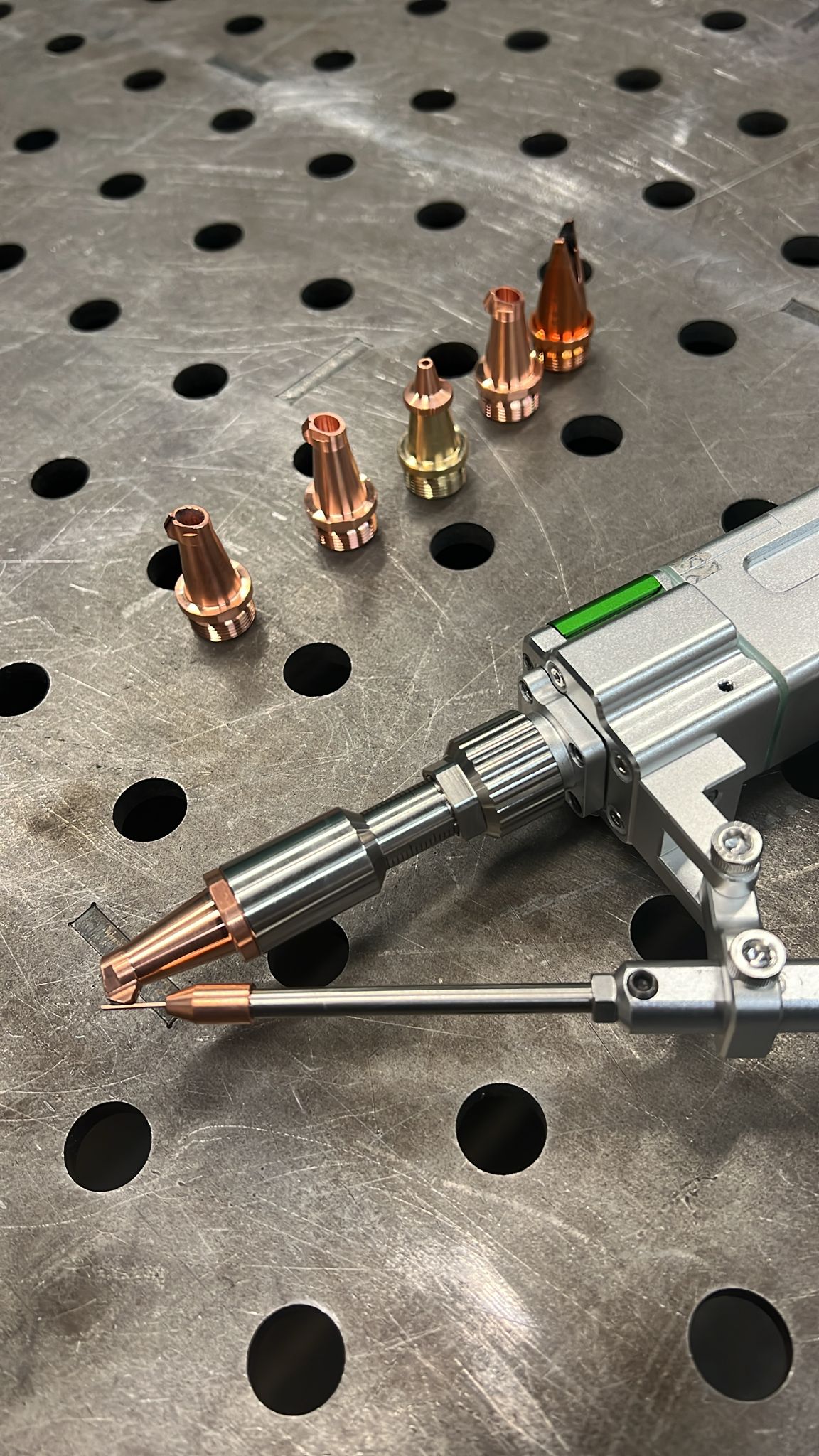

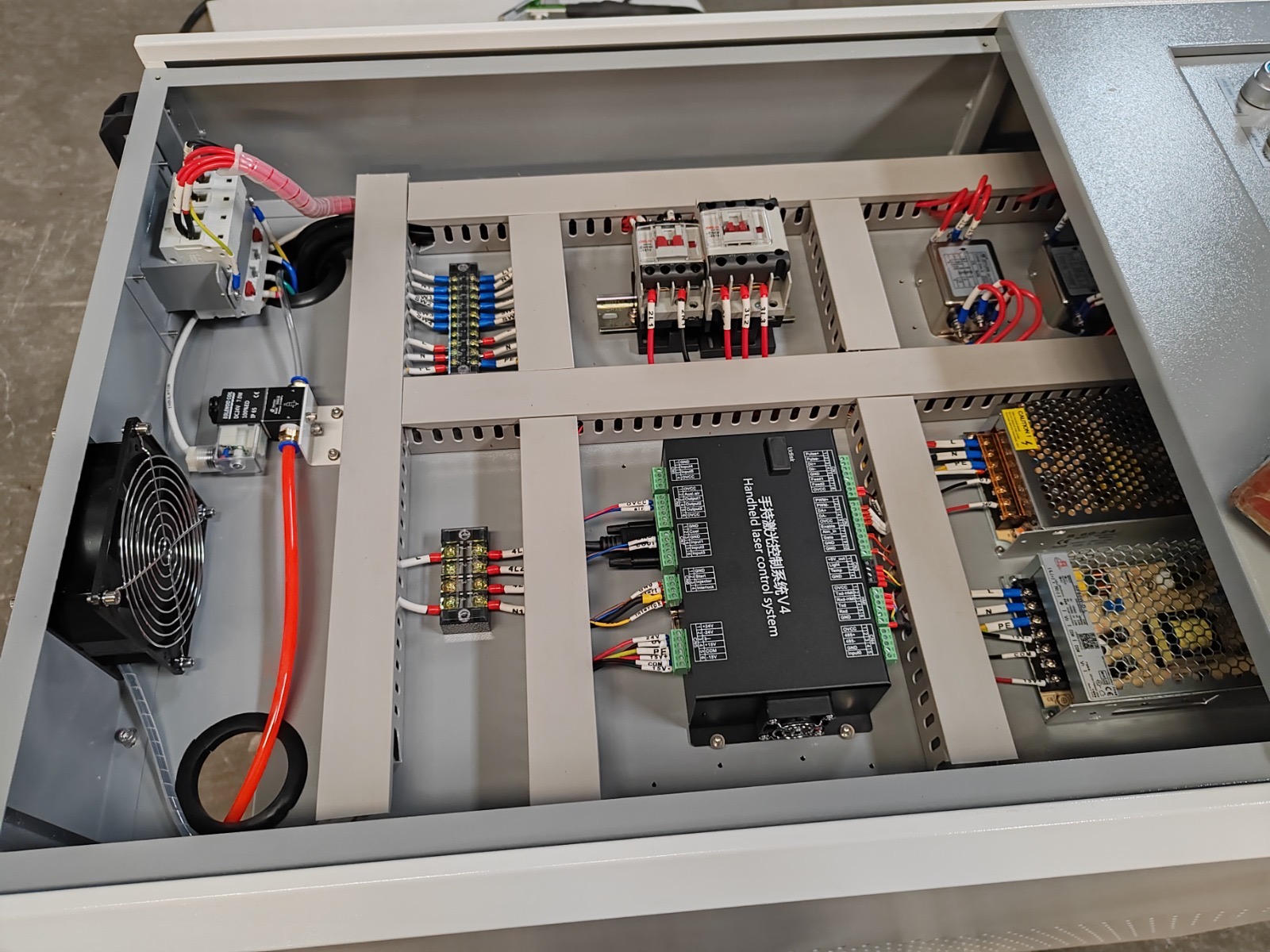

Only superior components are used such as Maxphotonics Laser Source - Hanli Water Chiller - Reflar laser Gun

Uk Full stock of spares & Consumables

Full Telephone support with our hands on experienced welding technicians

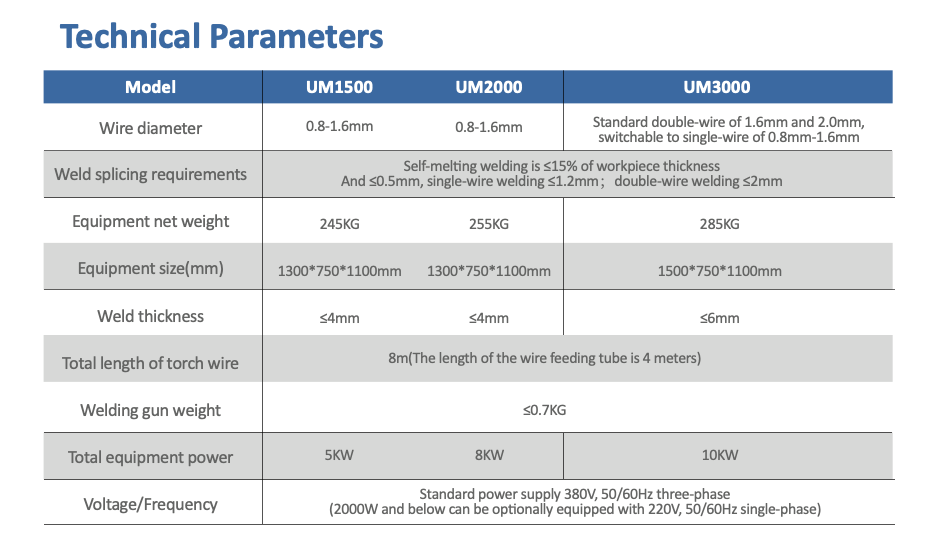

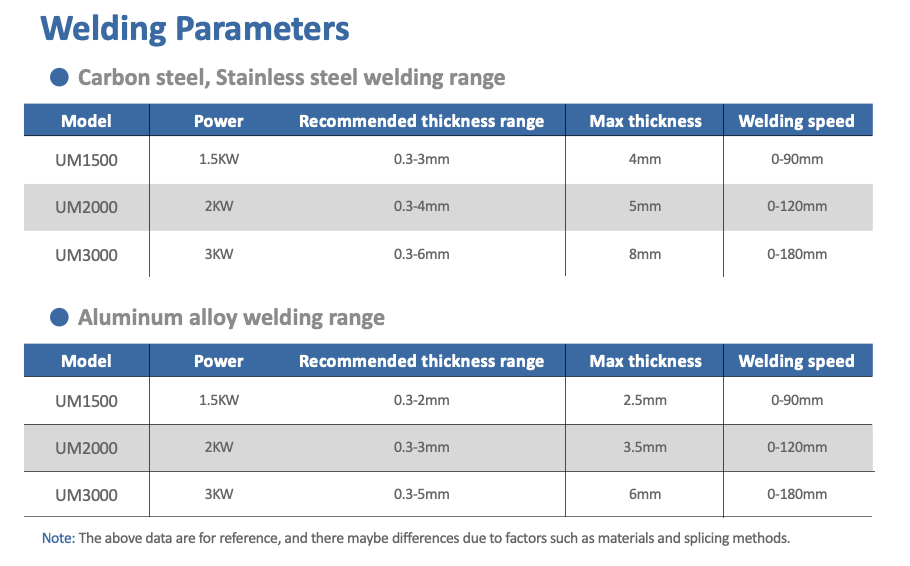

Model: Weld with Wire feed single or double

Weld - Cut - Clean Functions with 1.5, 2, 3kw Power

NEW UPGRADE : Our latest software coupled with Nozzle Change allows Laser Weld Cleaning Function

Testing Penetration & Weld Strength Samples

Laser WELD Safety

Even if you haven't purchased equipment from ourselves we are happy to assist and advise